Open Die Forging for Seamless Ring Manufacturing

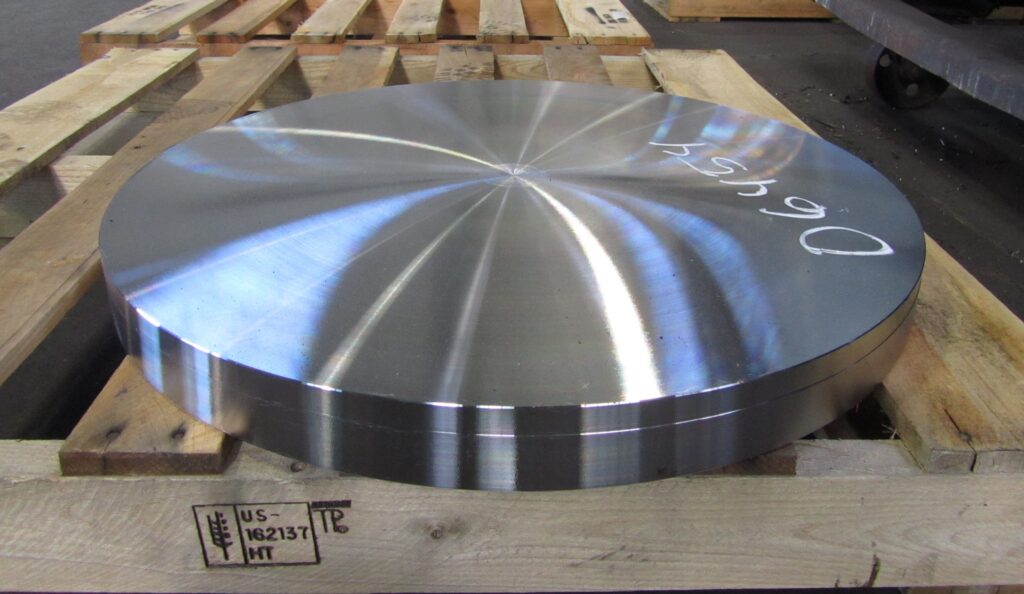

At Hammond & Irving, we also specialize in open die forging, a process that utilizes industrial hammers and presses to create seamless ring forgings outside the ring roller’s capabilities.

Our versatile 500 ton and 1000 ton forging presses enable us to manufacture seamless ring forgings with precision. These forgings can reach up to 20 inches in face height and weigh up to 1800 lbs. Additionally, we excel in forging smaller, seamless hammered rings, also known as mandrel forgings, ranging from 5 to 70 lbs, in various custom configurations.

Our skilled Hammersmen and Press Operators, with decades of forging experience, meticulously craft ring forgings to meet your specifications. As an added benefit, all our open die seamless rings undergo rough turning on the outer diameter. This process facilitates chucking and stock removal during finishing operations at our customers’ facilities.

Why Choose Hammond & Irving?

With our expertise in both seamless rolled rings and open die forgings, we offer a comprehensive solution for a wide range of ring forging needs. Whether you require seamless rings, forged discs, or short bars, we’ve got you covered.

Feel free to explore our offerings and discover how Hammond & Irving can meet your forging requirements.